Torque Monster: Open-Source Rim Motor

Torque Monster: Open-Source Rim Motor

Description: The Torque Monster is a that moves the stators to the rim of a wheel, leveraging the moment arm for massive torque output. Unlike traditional hub motors, this design:

- Simplifies wiring with single-coil segments.

- Uses an for efficiency.

- Is fully open-source under the TIC-OHSL license.

Why It Matters:

- E-bikes: High torque for cargo bikes or hill climbing—.

- Marine: without accessing the full shaft.

- Industrial: Direct-drive conveyors, cranes, or mills.

What makes this different?

The only real difference between a Torque Monster and most electric motors out there is it's size.

The Torque Monster is essentially is essentially a segment of a gigantic traditional brushless Outrunner.

What I am doing is taking a traditional 12N14P and turning it into a 72N84P out runner, except that instead of 72 stator teeth covering 360 degrees of arc, I will still use 12N on a 30 degree arc.

The 72 magnets are in an enormous rotor as compared to the 12N14P. By dragging all the action to the rim of the wheel the torque available is orders of magnitude greater. We don't need the the other 60 stators

It seems too simple to be true, but the maths seems to work out. If it's true, why aren't people doing it?

Electronic "gearing".

Because it now takes 6 full 12N cycles of the 12N stators for our 72 pole rotor to complete a single revolution, we effectively have a 6:1 gear ration. Add to the the choice of dLRK windings: https://www.bavaria-direct.co.za/scheme/common/ , HUGE moment arm, and smooth high torque is looking really possible.

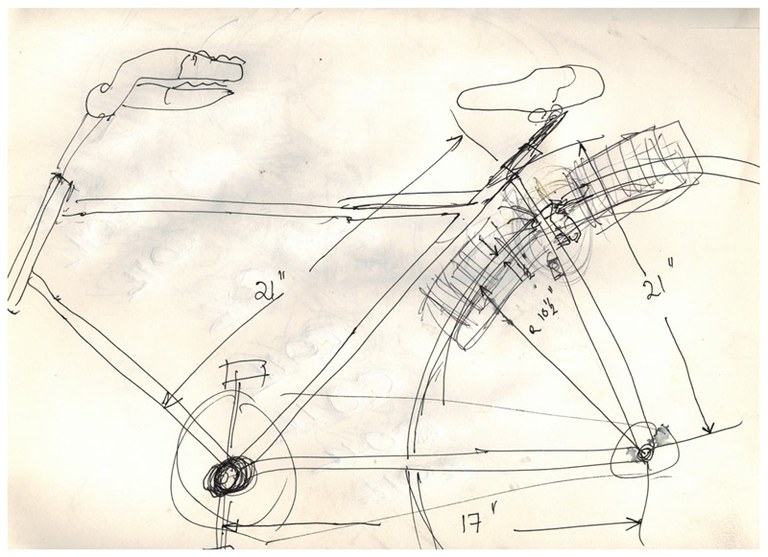

Early sketches and threshing the idea.

I found a series of sketches from years ago. Bjorn and I have been meeting on an almost weekly basis for years. Having recently returned to this idea, I found the original sketches from our "discussions". I put them in quotation marks because sometimes they look more like arguments than mere discussions. In some of these the argument is almost palpable. LOL See them here.

Building a prototype.

Having convinced myself of the validify of the concept I decided to see if I could build one.

Rotor

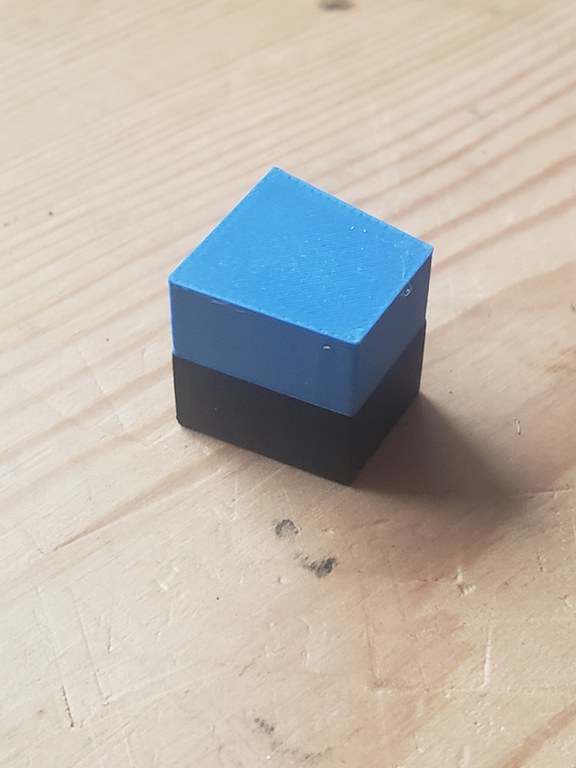

I measured up the old 26 inch cruiser in my garage and found it has 36 spokes and that the spoke nipples are 4 mm diameter. I figured two magnets per spoke looked like a good size so I printed up some "faux magnets" :

and set about mounting them near the rim:

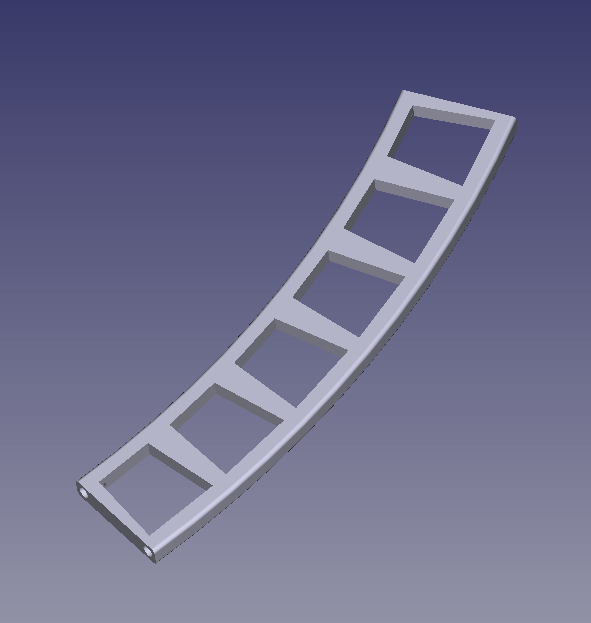

I was pleasantly surprised to learn how easily they assembled and was more than a little shocked at how solid the mounting strips are.

LAMS - Linear Arc Motor Segments

The main difference between a Torque Monster and traditional out runners is the moment arm of the magnets. By moving the stators and rotor from the hub of the bicycle wheel to the rim we can increase this monument arm by orders of magnitude.

But we don't want to have stators 60 or more stators also out there at the rim - too many, too heavy, too expensive, impractical.

It occurred to me that in a traditional out runner the stators are not "aware" of how many magnets are on the rotor, all that is needed is for a magnet to "appear" at the right place at the right time. Hang on, then that means I can have as many magnets as I want on my rotor and the stators won't care?

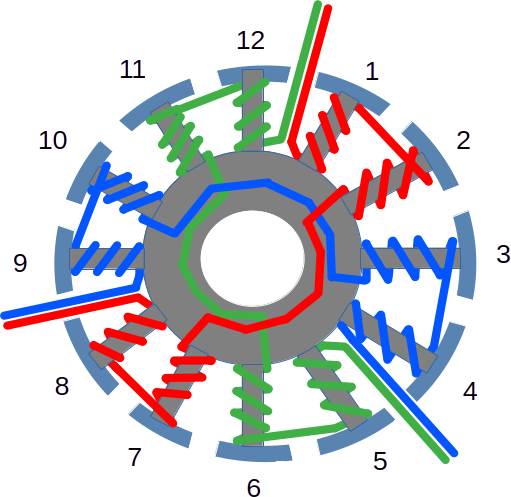

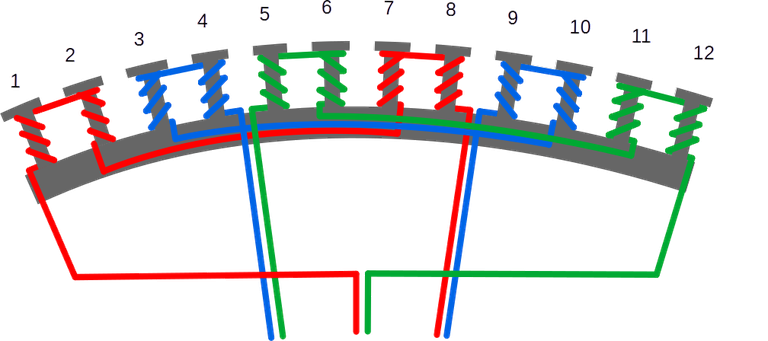

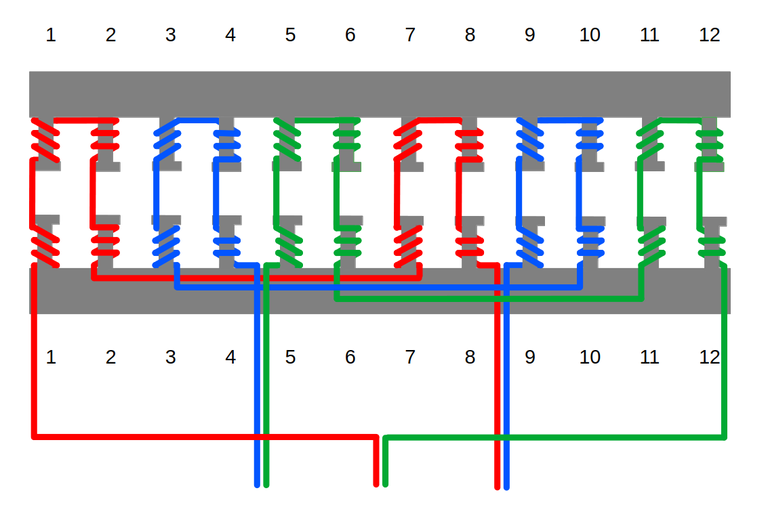

Take the well known example of a 12N14P outrunner, as described in three of the four examples here: https://www.bavaria-direct.co.za/scheme/common/

Peeling a motor.

This is fundamental to the practicality and flexibility of highly displaced LAMS.

I believe I can take essentially any configuration electric motor, specifically radial flux , and "peel" it out to a 30 degree arc the diameter of the wheel rim. A 12N14P motor has it's physical dimension determined by it's 6:7 ratio of stator teeth to magnet poles. That ratio of teeth:poles is what determines "when" a given magnet is influenced by any one stator. Once this realization hit me things became beautifully simple. I always like it when a simple solution presents itself as I believe this means I am on the right track.

All I need to do is maker sure the physical dimensions of the stators follows the 6:7 rule and the rest is inherently bound by nature of a wheel.

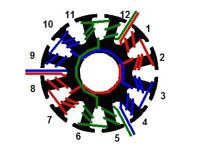

In an effort to clearly understand this winding scheme I made my own graphic of it,

dLRK-Evo winding scheme

then "peeled" it:

As far as I can tell the two are identical windings, other than the radial arc length. As long as the magnets "appear" at the right time I believe this should "just work".

Axial Flux

The traditional "can" motors are a Radial Flux design and the Torque Monster is an Axial flux motor, so the same wiring scheme can be used by treating each tooth of the radial layout as a pair in the Axial design. Again, the scheme is the same dLRK-Evo but each stator toot is split in the middle and the rotor is located between them.

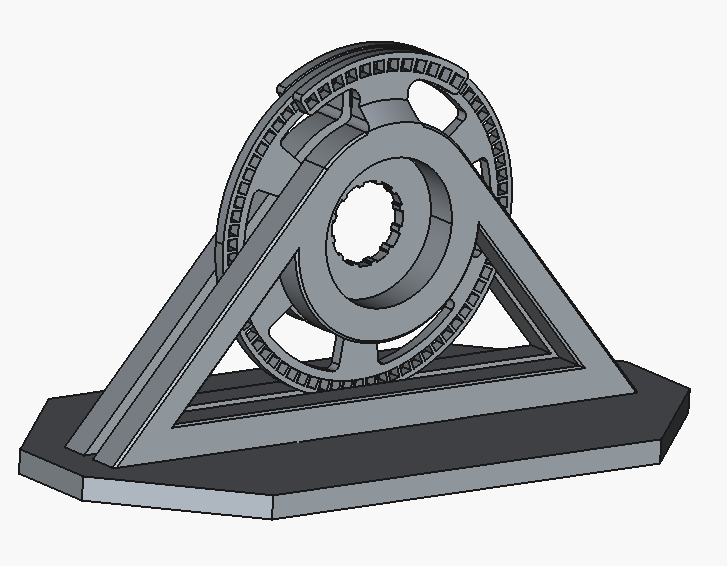

Enter FreeCAD

So I started out modelling a standard 12N14P based on some magnets I has on hand. I chose the 12N14P because it is almost ubiquitous in the RC world. It has low cogging characteristics and is generally regarded as a "good" layout. It is a well proven design.

I chose FreeCAD for the modelling because of it's wonderful parametric features and Open Source ethos. I want all the tools used in this project to be freely available for anyone to reproduce so I and set about learning it's parametric possibilities. The goal here was to produce a spreadsheet based assembly driven by a specific wheel's dimensions, so anyone can go to their bicycle, measure the diameter of the rim, the hub (needed to calculate spoke angle and ensure magnets to not interfere with them), spoke count, and spoke nipple diameter.

By entering those 4 parameters we can calculate the exact size, shape and number of magnets required.

After some steep learning, and challenges with FreeCAD doing a spreadsheet driven parametric model, I decided to put the parametric motor on the back burner and just modeled it with static values.

What is this 6:7 all about?

My admittedly limited understanding of things tells me a 6N7P, (or maybe a 6N5P? - anyone with better understanding of the pros and const of a 12N10P vs 12N14P please enlighten me!) is the smallest number of stators that can accommodate the three phased pairs used. A 12N14P is essentially two 6N7P motors "joined" is it not? I believe, and soon will have evidence whether I am right or not, that all I need to do is put 2 "6 stator teethed (2 x 6N)" stators in an arc that meets the 6:7 physical dimensions of the equivalent 12N14P outrunner and "voila" - a "Linear Arc Motor". I don't think the 2 6N LAMS even need to be right next to each other, they just need to be spaces 2 teeth (or any even integer for that matter) and a magnet will "arrive" in the right place at the right time.

If I am right the simplicity and elegance delights me.

Files and Resources

| Resources | Format | Description |

| CAD Files | FreeCAD/STEP | . |

| Schematics | PDF/SVG | Wiring and magnet arrangement. |

| Bill of Materials | CSV | Parts list for the prototype. |

| Build Instructions | Markdown | Step-by-step assembly guide. |

License

This project is licensed under the TIC-OHSL. By using these files, you agree to:

- Attribute the work to Paul O’Rorke and link to theidea.club.

- Share improvements under the same license.

- (Optional) Contribute 2% of revenue (over 333.33 oz gold/year) to support the project.

How to Contribute

- Test the Design: Build your own Torque Monster and share your results.

- Improve the Plans: Submit modifications or optimizations.

- Sponsor the Project: Help fund materials or development time.

- Liberapay

https://liberapay.com/theIdea.club/donate - Stripe

(Coming soon)

- Liberapay

Call to Action

"This project is a proof of concept for open-source hardware. If you believe in the mission, get involved—whether by testing, improving, or sponsoring. Together, we can redefine how motors are designed and shared."