Bjorn Lampson's Projects

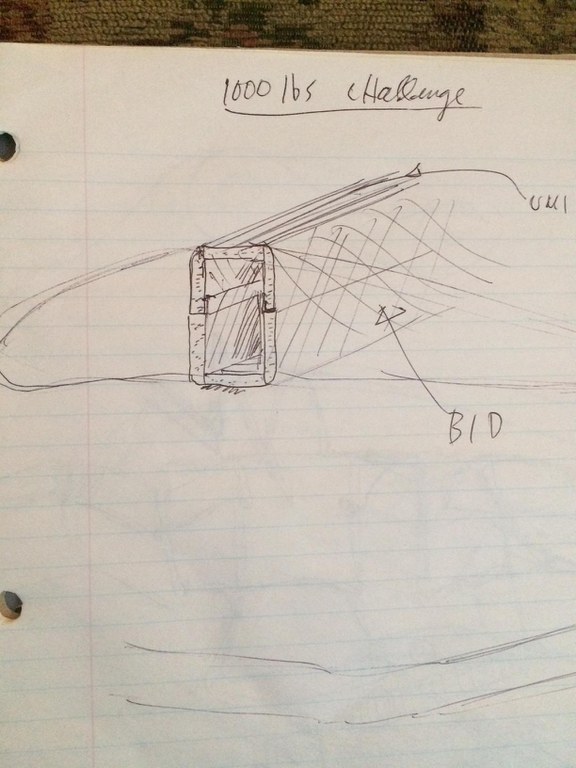

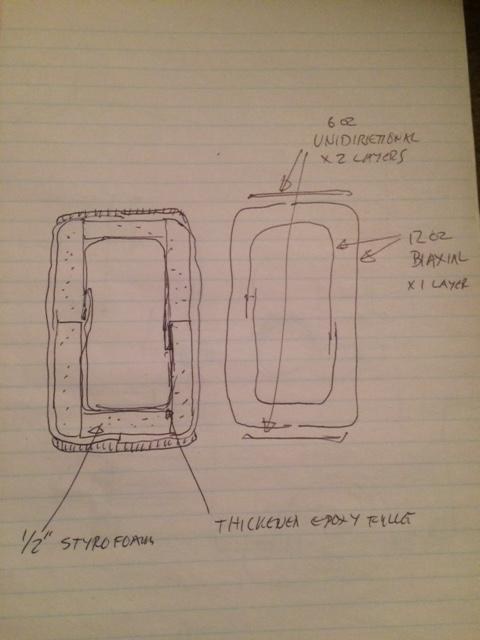

1000 pound beam challenge

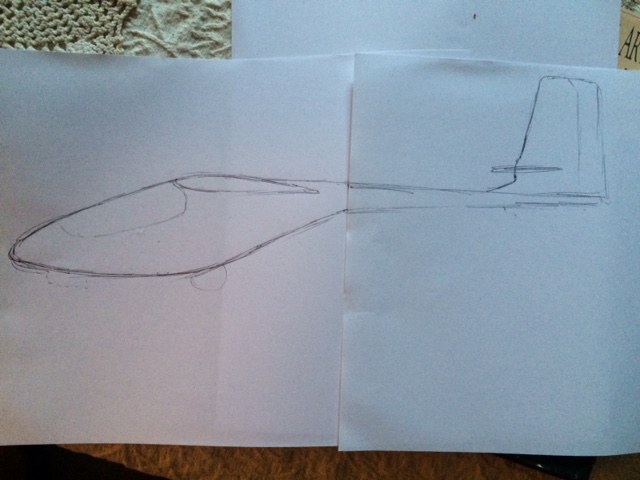

Glider project

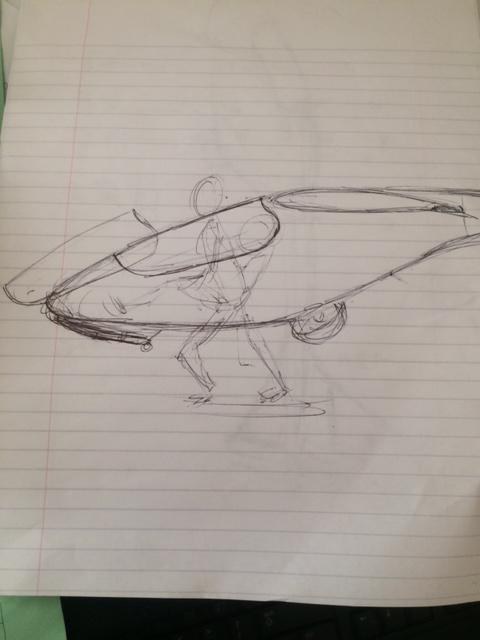

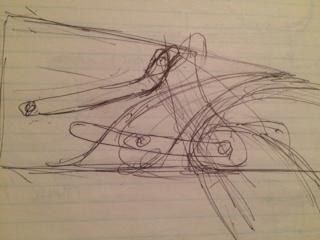

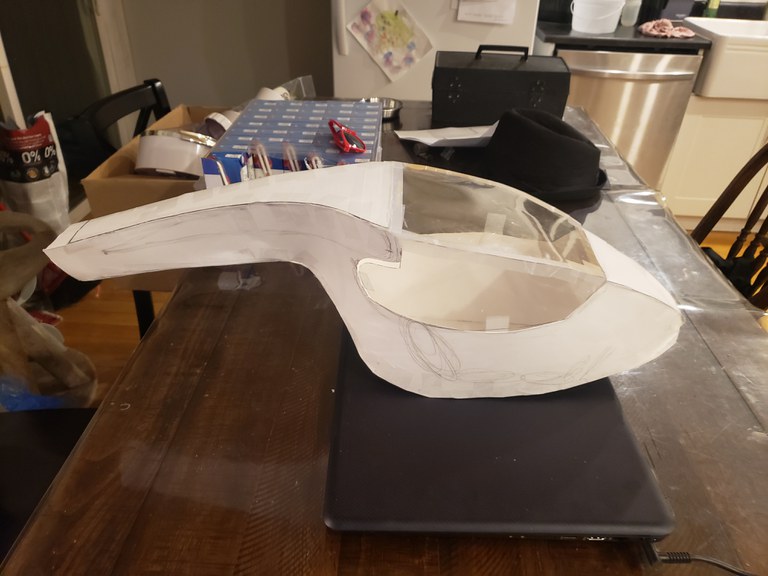

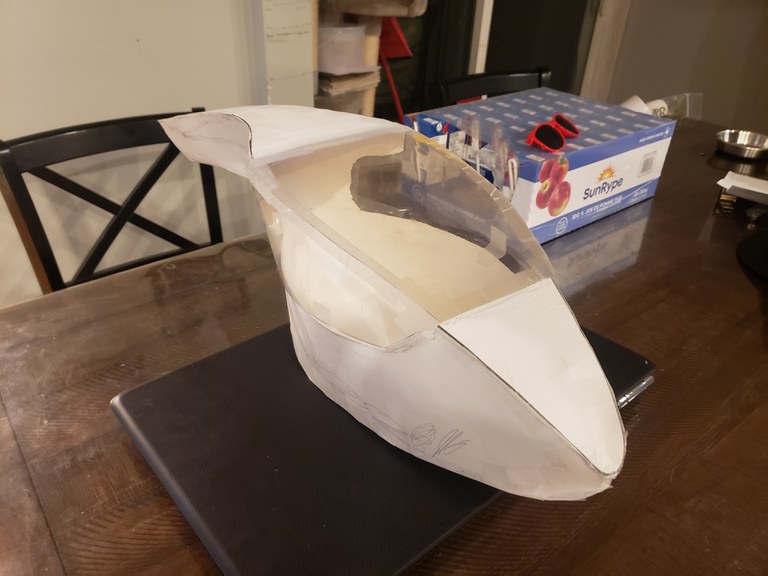

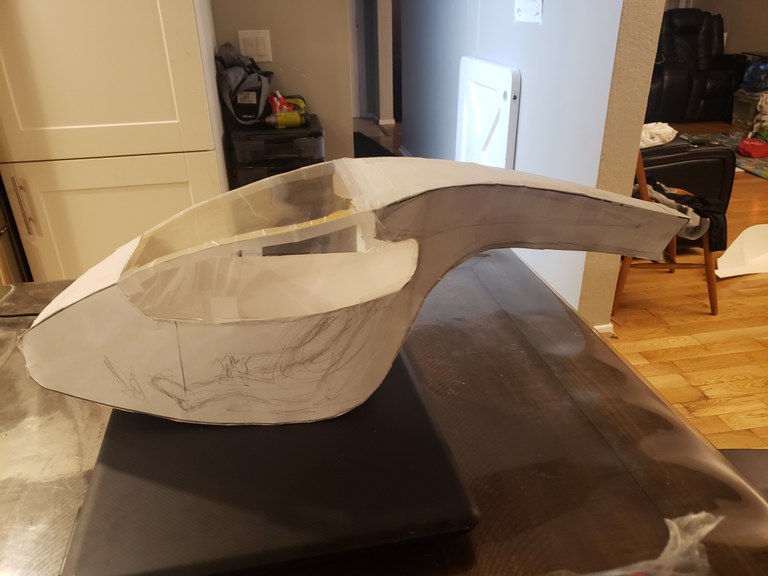

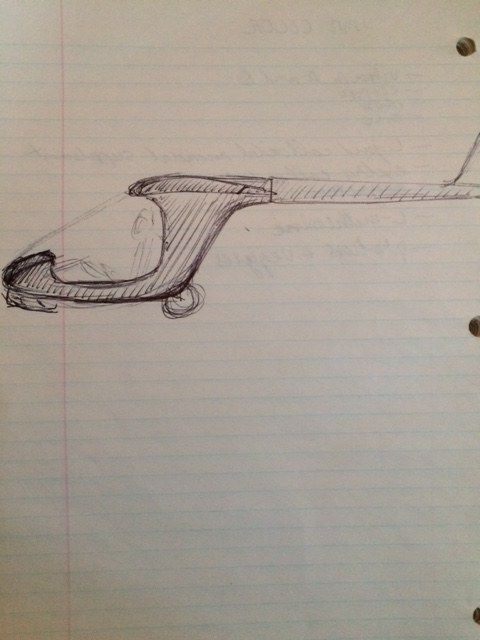

Amihan 42 foot launchable glider

The Amihan 42 will be a single seat high wing foot-launchable glider that could compete in the high end hang glider category. It will have three axis controls, stabilator for pitch control, fin and rudder for yaw, and spoilerons for roll and yaw during launch as your feet will not be on the pedals at that time. For take off the full span slotted flaps will be at 10 degrees, with an optional setting of 25, and 40 degrees for landing. To manage low speed flight close to stall, there will be a stall fence at the outer 75% position of each wing and a leading edge slot from the stall fence to the tip. The spoilerons will be just aft of the leading edge slots to manage roll control at any speed. Spoilerons will also slow down the inner wing in turns eliminating adverse yaw.

With a gross weight of 385 lbs and a target stall speed of under 20 mph I envision the Amihan 42 to be ideal for beach soaring or dune gooning. Beach soaring usually has a good steady sea breeze and enough space to soar the shoreline and land back at the launch site. Beach soaring requires precise flying and positive control response.

Specifications:

- wing span 42'

- chord 4'

- length 20'

- empty weight 100 lbs

- gross weight 385 lbs

- stall speed 20 mph no flaps

- flap range 10*, 25*, 40*

Other ideas for inspiration and comparison- Klingberg wing https://www.youtube.com/watch?v=fSp2kP9DTbM

- Archaeopterex https://www.flixxy.com/foot-launched-glider.htm

- Arnes http://www2.arnes.si/~cetim6/fls1.htm

- Carbon Dragon http://www.carbondragon.us/

- Super Floater https://www.youtube.com/watch?v=qO35z9cElVo

- Arienne Swift https://www.flymanilla.com/Equipment/SWIFTLITEULGlider/tabid/344/Default.aspx

- Atos https://www.aeroexpo.online/prod/air-gmbh/product-171220-2809.html

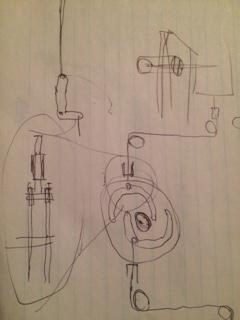

Amihan 42 Control System

Cam plate to control spoilerons to eliminate nul point slop

Electricity from Ground

Used oil stove for shop heat

Used oil stove for shop heat

Chimney connector installation.

Adding the oil feed connections.

Connectnging the chimney

Conclusion

After hooking up the chimney and fuel lines, I grabbed a used oil jug to do a test burn. What came out of the jug was mostly coolant!! Ugh! So a few hours later after the oil tank was cleaned out and reinstalled, I was able to do a test burn. I had to soak a piece of rag in oil and put it inside and lit it with a blow torch. Once lit, the stove burned quite well apart from the poor weld at the bottom which leaked oil. I will have to fix that before I can use it properly. The stove makes quite a bit of roaring noise, fuel flow control is good. I might have to add a blower to make it burn a bit cleaner, but all in all it was a success!